CNC

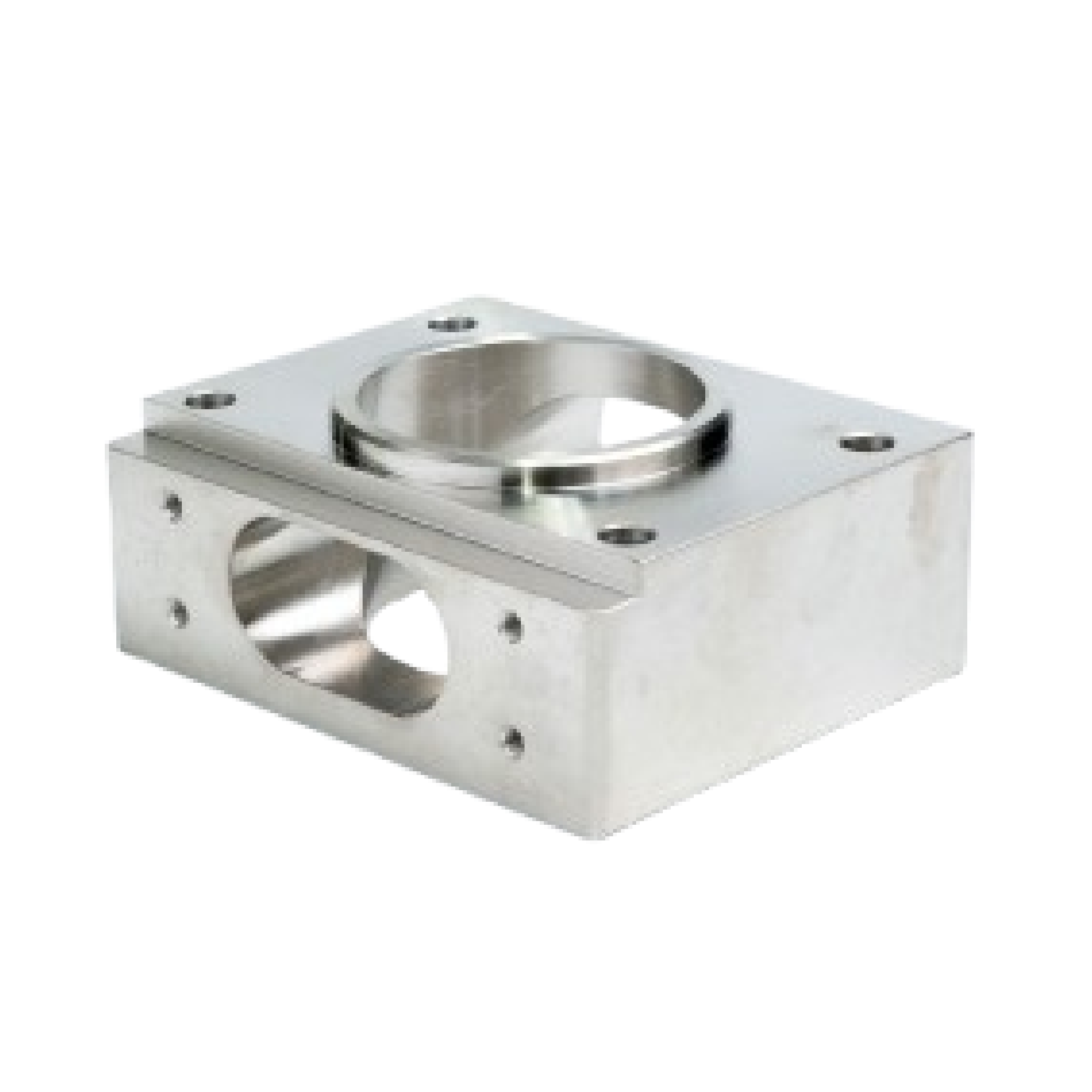

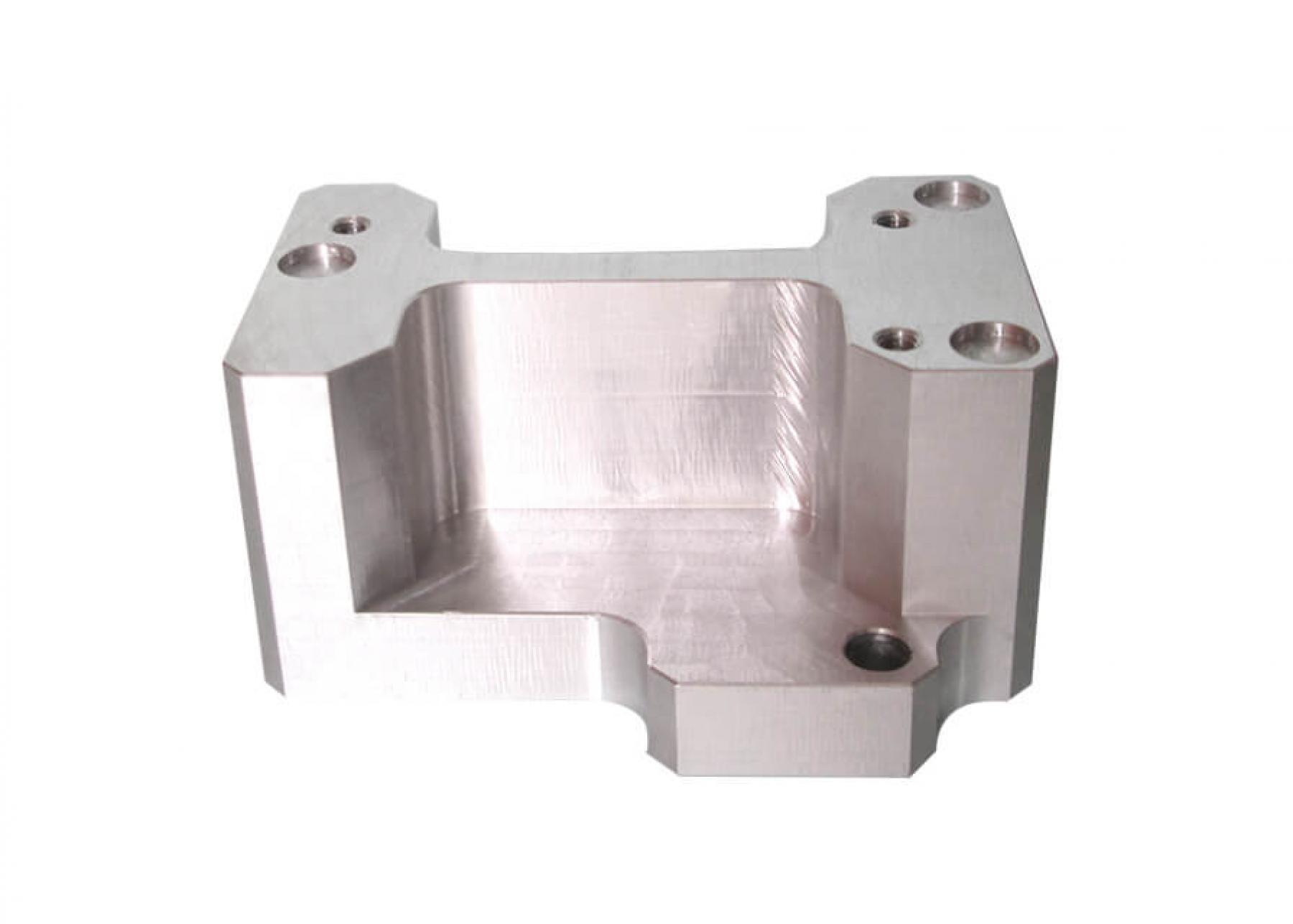

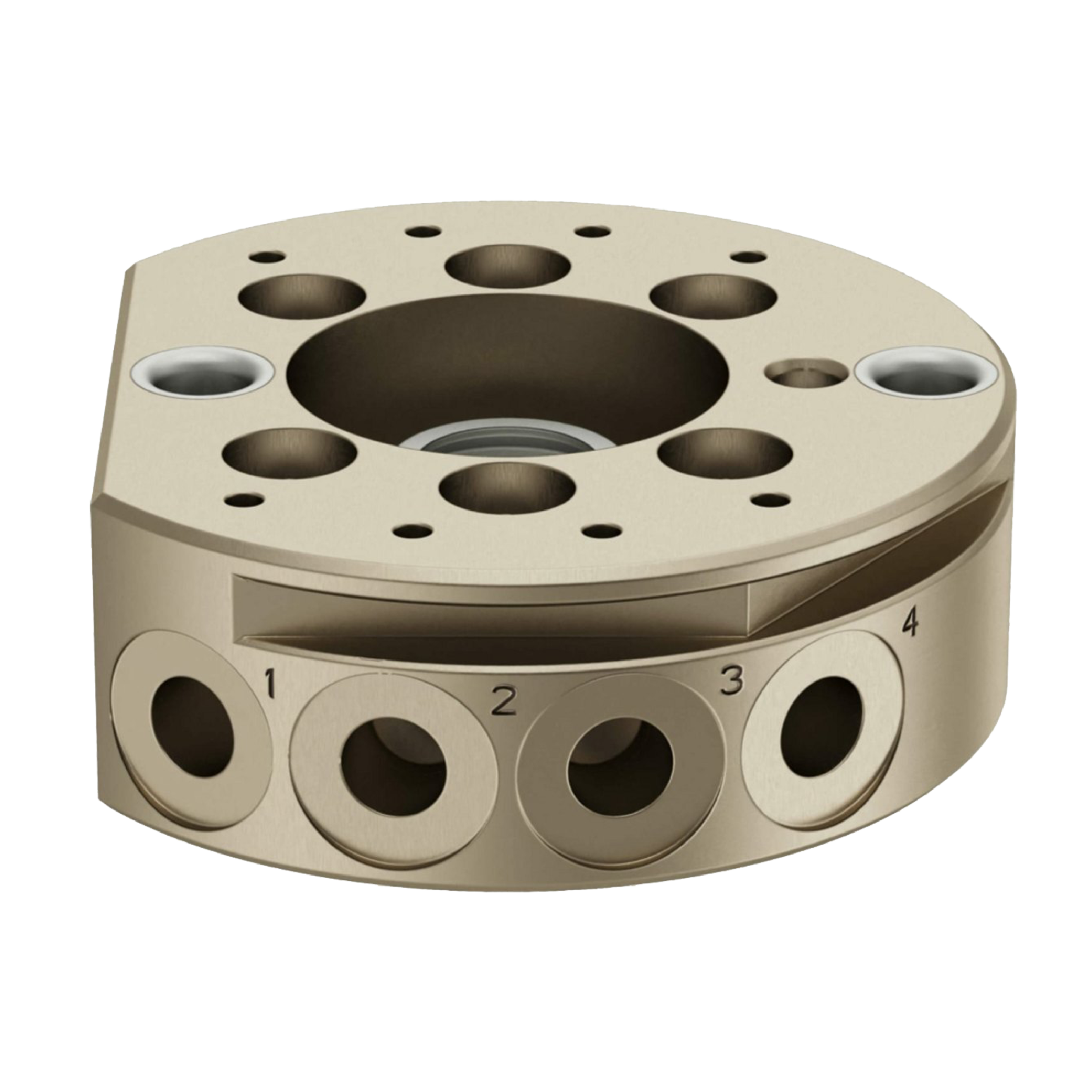

KITISOTECH CNC machining services deliver end-to-end solutions, from mass production to custom-made parts. With advanced CNC machines (3-axis, 4-axis, 5-axis; milling, turning, drilling) and a skilled engineering team, we are capable of machining everything from simple components to complex 3D structures with high precision and consistent reliability. Trusted by industries such as automotive, semiconductors, electronics, medical devices, UAVs, and aerospace, KITISOTECH ensures tight tolerances, superior surface finishing, and optimized lead times.

|

|

|

CNC Milling Service |

CNC Turning Service |

CNC Drilling Service |

| KITISOTECH provides high-precision CNC milling on 3, 4, and 5-axis machines, ideal for complex parts in metals, plastics, and molds with tight tolerances and smooth finishes. | KITISOTECH offers high-precision CNC turning for shafts, rings, and other round or symmetrical parts in metals and plastics, ensuring accuracy, consistency, and smooth finishes. | KITISOTECH provides CNC drilling for precise and consistent hole-making in metals and plastics, supporting both simple and complex part designs. |

This service is particularly suitable for products with complex geometries, multiple surfaces, stringent stability requirements, tight tolerances, and industrial-grade surface quality.

Item |

Specification |

|

Precision |

Maximum tolerance for milling & turning: 0.XXXX |

|

CNC Part Size |

Up to 1.5 m × 0.7 m |

|

Vertical Milling |

1,300 × 670 × 625 mm (51 × 26 × 23.5 in) |

|

Horizontal Milling |

800 × 750 × 850 mm (31.5 × 29.5 × 33.5 in) |

|

Turning |

D481 × L1,275 mm (D18.9 × L50 in) |

|

Tapping Depth |

40 – 50 mm |

|

Through-hole Diameter |

1.2 m; 3–30 mm; 3 m; 0.3 m |

|

Surface Coating |

Up to 6 m × 25 m × 23 m |

|

Anodizing |

Up to 1.5 m; 3 m |

KITISOTECH continuously expands its machining capabilities to meet global standards. With advanced CNC equipment, rigorous quality control, and proven experience serving international clients, we provide competitive pricing, tight tolerances, and a wide selection of materials and finishing options.

Whether in prototyping or mass production, KITISOTECH is your trusted CNC manufacturing partner worldwide.

CNC machining service materials

We offer flexible CNC machining across a wide range of materials, including metals (aluminum, steel, stainless steel, titanium, copper, special alloys) and various types of plastics. With extensive material expertise and diverse processing capabilities, KITISOTECH ensures every CNC-machined part meets the highest quality standards and fulfills your specific requirements

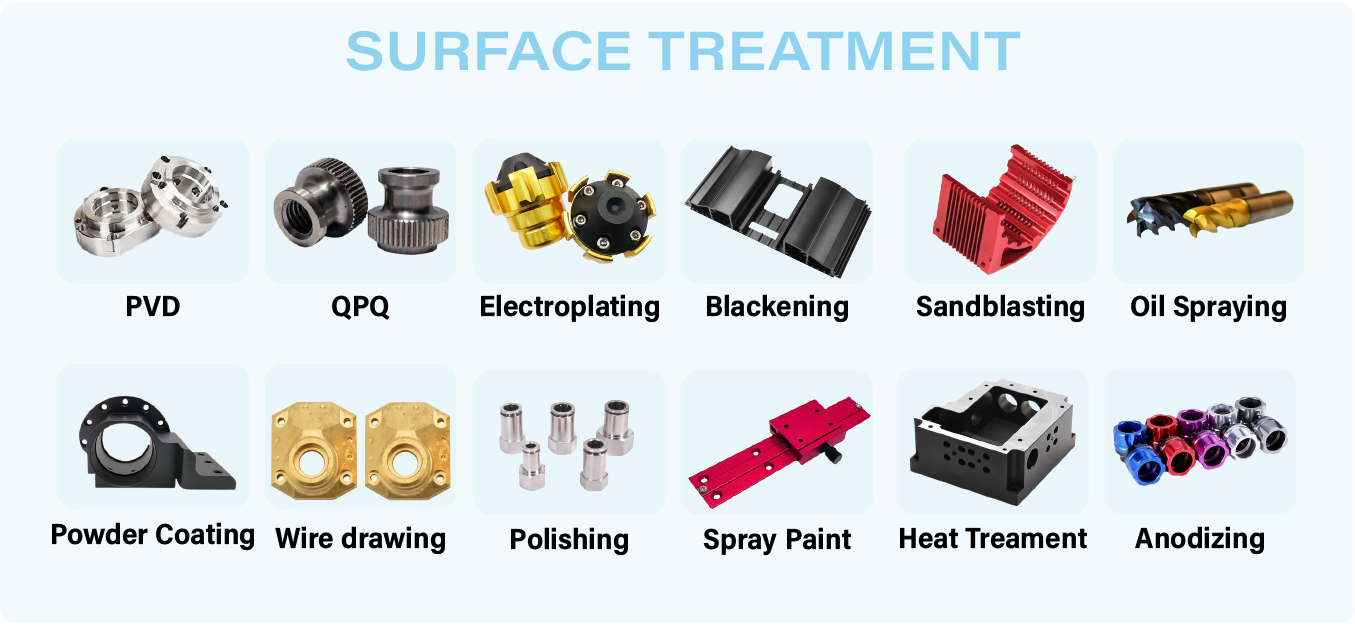

Mechanical Finishing and Surface Treatment Services

After milling, turning, and drilling, KITISOTECH further enhances the precision and functionality of parts through mechanical finishing processes. Techniques such as threading, reaming, broaching, and grinding ensure tight tolerances, high accuracy, and smooth surface finishes for CNC components.

Beyond precision, KITISOTECH improves the durability and aesthetics of products with advanced surface treatment solutions. Methods such as anodizing, powder coating, electroplating, PVD, QPQ, sandblasting, and heat treatment enhance corrosion resistance, increase hardness, and deliver consistent, high-quality finishes. With strict quality control and advanced technology, we guarantee superior and reliable surface performance for every part.

Applications of Custom CNC Machining Services

Custom CNC machining has a wide range of applications across various industries. Examples of CNC prototyping applications include semiconductors, medical devices, UAVs/drones, electronics, automation, aerospace, and high-tech sectors.